In the evolving landscape of advanced manufacturing, prepregs stand as one of the most advanced and efficient composite materials available today. These materials combine reinforcing fibers—such as carbon fiber, glass, or aramid—with a partially cured resin system, most often epoxy. Known for their precision, consistency, and strength, epoxy prepreg, aerospace prepreg, rapid-cure prepreg, and carbon fiber prepreg are revolutionizing how industries design and produce high-performance components.

Epoxy Prepreg – High Strength and Reliability

Among the most popular and versatile composite materials is the epoxy prepreg. It uses an epoxy resin matrix pre-impregnated into reinforcing fibers to achieve maximum uniformity and durability. The resin is in a semi-cured (B-stage) state, making it easy to handle and shape before final curing.

Manufacturers prefer epoxy prepreg for its predictable mechanical properties, superior adhesion, and excellent fatigue resistance. These materials are used in wind energy, automotive structures, industrial tools, and even aerospace parts. Their high fiber volume fraction and low void content ensure stability and strength across various applications.

Aerospace Prepreg – Precision and Performance in the Sky

When it comes to flight-critical components, aerospace prepreg is the gold standard. These materials must perform under extreme conditions—temperature changes, mechanical stress, and exposure to humidity—while remaining lightweight and durable.

Aerospace prepreg systems often use high-grade carbon fiber prepreg combined with temperature-resistant epoxy resins. The result is a structure that maintains integrity even at temperatures above 200 °C. Such prepregs are essential for aircraft fuselages, wings, and interior panels, where weight reduction translates directly to improved efficiency and lower fuel consumption.

The aerospace industry’s strict certification standards demand consistent quality and traceability, and aerospace prepreg materials are specifically designed to meet those expectations.

Rapid-Cure Prepreg – Speed Without Compromise

Modern manufacturing faces a growing need for faster production cycles. This is where rapid-cure prepreg technology comes in. By modifying the resin chemistry, manufacturers can significantly reduce curing time—from several hours to mere minutes—without sacrificing performance.

Rapid-cure prepreg enables cost-effective, high-throughput production for industries such as automotive, sports equipment, and consumer goods. The shorter cycle time allows for scalable manufacturing, combining the benefits of advanced composites with the speed of modern production lines. These prepregs are ideal for manufacturers seeking to balance quality and efficiency.

Carbon Fiber Prepreg – Lightweight Power and Elegance

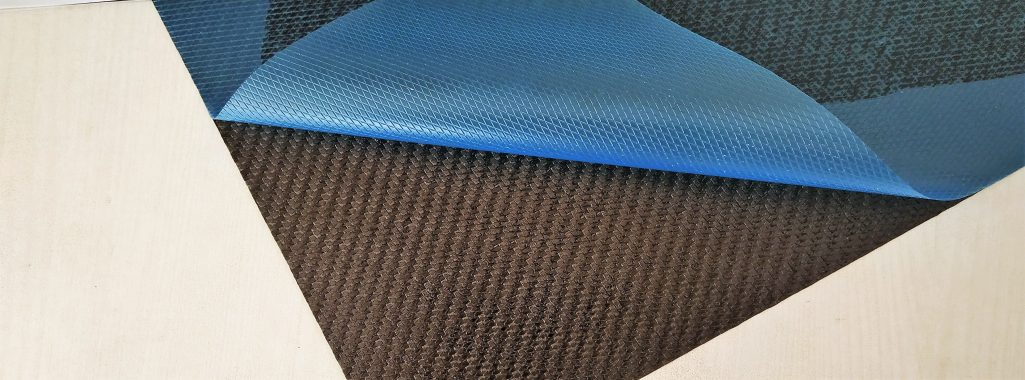

At the top of the composite hierarchy is the carbon fiber prepreg, prized for its unbeatable strength-to-weight ratio and sleek aesthetic appeal. It offers high stiffness, superior fatigue resistance, and minimal thermal expansion—all vital for high-performance engineering.

Carbon fiber prepreg materials are widely used in aerospace, automotive racing, and high-end consumer products. They allow engineers to create complex shapes with precision while maintaining structural integrity. Whether used in aircraft wings, sports cars, or bicycles, carbon fiber prepreg represents the perfect fusion of performance and design.

Advantages for Modern Manufacturing

The adoption of epoxy prepreg, aerospace prepreg, rapid-cure prepreg, and carbon fiber prepreg offers a wide range of benefits for manufacturers seeking top-tier quality and performance:

• Exceptional strength-to-weight ratio – Critical for reducing component mass while maintaining strength.

• High consistency – Factory-controlled resin impregnation ensures minimal variation.

• Faster production cycles – Especially with rapid-cure prepreg technologies.

• Enhanced fatigue and thermal resistance – Ideal for demanding environments.

• Design flexibility – Supports intricate geometries and integrated structures.

• Improved efficiency and reduced waste – A result of precise material control and repeatable processes.

Challenges and Industry Trends

While prepregs deliver remarkable advantages, they also come with unique challenges. They require refrigerated storage, specialized handling, and dedicated curing equipment such as autoclaves or press systems. However, innovations in out-of-autoclave (OOA) and rapid-cure prepreg systems are overcoming these barriers.

Future trends indicate a rise in sustainable resin systems, recyclable carbon fiber prepreg technologies, and smart manufacturing processes. As the industry pushes toward eco-efficiency and faster production, epoxy prepreg and aerospace prepreg will remain at the core of composite innovation.

From aircraft fuselages to electric vehicles and wind turbine blades, prepregs are shaping the future of lightweight and durable manufacturing. The combination of epoxy prepreg, aerospace prepreg, rapid-cure prepreg, and carbon fiber prepreg represents the next generation of high-performance materials—engineered for speed, precision, and sustainability.

As technology advances, these prepregs will continue to drive progress across industries, defining the future of structural innovation and composite excellence.